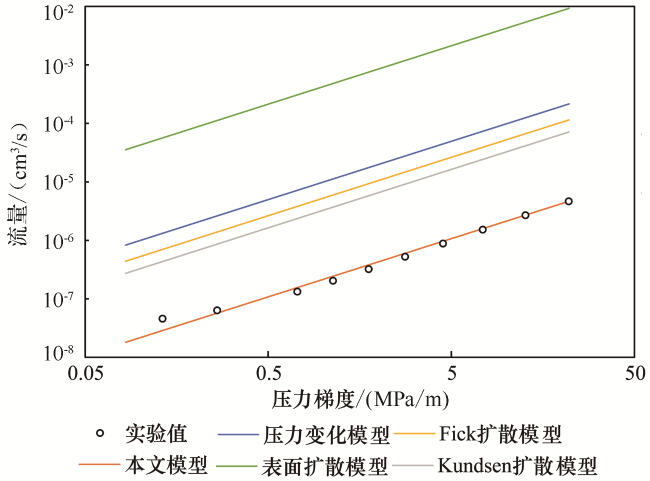

根据前人研究,对于达西流、滑脱流、Fick扩散、Kundsen扩散以及表面扩散等多种流动的耦合机制,还没有形成一个成熟的、完整的体系。JAVADPOUR等

[4-5]通过实验研究引入表观渗透率概念,建立Knudsen扩散理论,提出了一种适用于纳米孔隙中流体渗流的理论模型;李晓强等

[6]建立了考虑页岩机制中达西流和扩散流的双重流动机理模型,认为忽略基质中的扩散流动将严重低估气井的产量;李智峰

[7]建立了圆柱管内的平面单向稳定渗流数学模型,认为页岩的表观渗透率远远大于达西渗透率,孔隙半径越小,则两者比值越大,随着压力降低,Kundsen扩散作用不断增强;刘禹

[8]建立了考虑滑脱和扩散作用的径向和一维流动模型;盛茂等

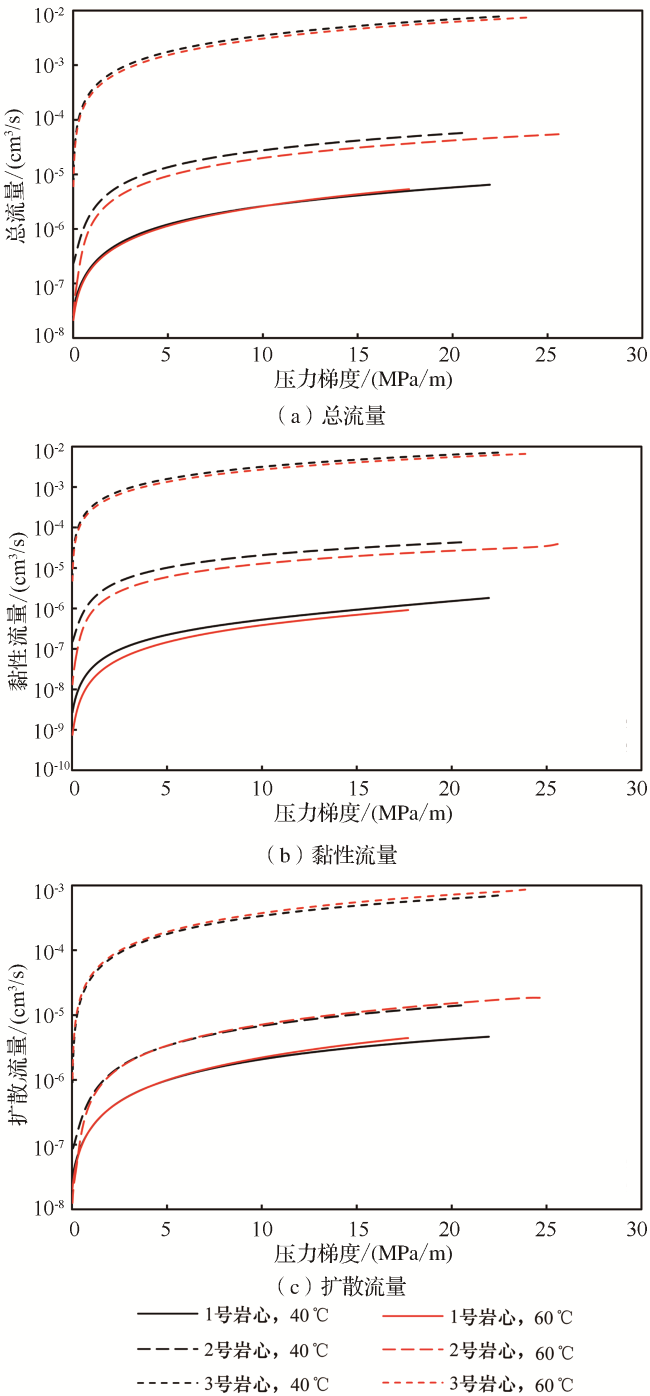

[9]建立了考虑孔内扩散、孔壁表面扩散、黏性滑脱流动和气体解吸附等多种流动机理的瞬态流动毛管束模型,认为孔壁表面扩散是页岩孔隙中不可忽略的传质方式,且表面扩散流量对总流量的贡献随孔径减小而增强;糜利栋等

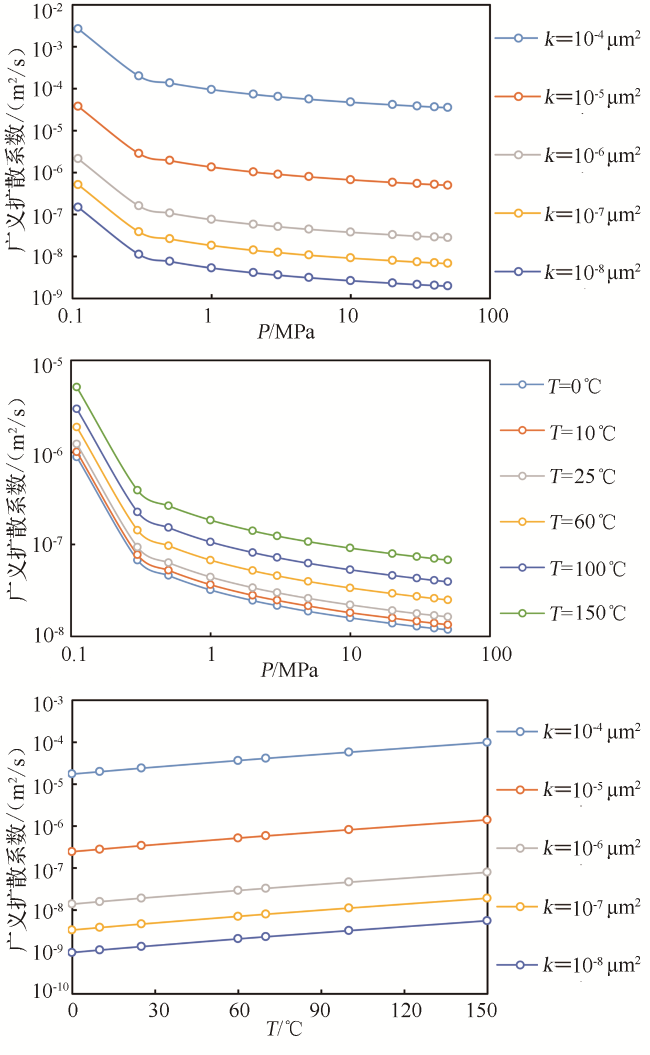

[10]建立了裂缝渗透率理论计算模型和基质渗透率理论计算模型,认为基质渗透率受气体滑脱效应和扩散效应影响,其渗流能力由温度、孔隙压力和孔隙直径共同决定;WASAKI等

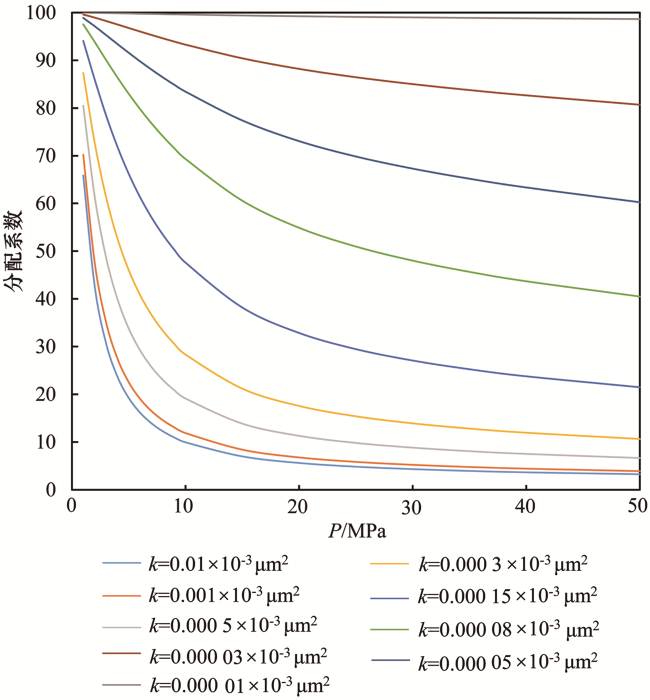

[11]建立了考虑吸附、扩散和应力敏感的视渗透率模型,认为孔隙压力较高时渗透率应力敏感较强,随着孔隙压力降低,黏性流减弱,扩散流增强,视渗透率增大;曹成等

[12]分别建立了考虑吸附、滑脱和自由分子流动效应的有机质渗透率与无机质渗透率模型;李武广等

[13]等基于Fick第二定律求解得到扩散系数的数学解析解,并分析页岩扩散能力的主要影响因素。

甘公网安备 62010202000678号

甘公网安备 62010202000678号